アルミ押出形材欠陥検出

EM

押出管理

RCDIGITAL,Inc.

August 2019

1

アルミ押出形材欠陥検出

1-1システムの特徴

押出作業者は、生産性をあげるために、押出速度をできる限り高く設定します。その時に、アルミ形材の表面を見て、異常がないか確認します。

これは、熟練作業者にしかできません。

そのため、誰でもが生産性を上げることができるように、ディープラーニングを使用したコンピュータによる押出形材欠陥検出システムをつくりました。

システムには以下の機能があります。

1 自動/手動の押出中の形材画像の収集。

2 ディープラーニングによる予測モデルファイルの読み込み。

3 自動/手動の形材の欠陥検出。

ディープラーニングの適用領域は音声、画像、言語があります。画像については、2015年にグーグルが、2016年にはマイクロソフトが、ディープラーニングは人間の識別能力を超えたと宣言しました。

ディープラーニングが最も得意とする分野は画像認識です。そのため、工場で、画像から異常を検出するのにディープラーニングを使用するのは合理的です。

アルミ押出形材欠陥検出の制御への応用としては、欠陥の兆候を検出したら、設定押出速度を傾斜させるなどが考えられます。

予測モデルを作成するプラットフォームには、、クラウドでは以下があります。

Azure Machine Learning、Amazon Machine Learning ,Bluemix IBM Watson 、Google Cloud Platform。

プログラムを作成するフレームワークとしては以下があります。

CNTK、TensorFlow、Caffe、Chainer、Keras、Theano

予測モデルはファイルとして読み込むことができます。画像データを蓄積すれば、新しいモデルは欠陥検出率がよくなります。新しいモデルに入れ替えれば、生産性が良くなります。

1-2

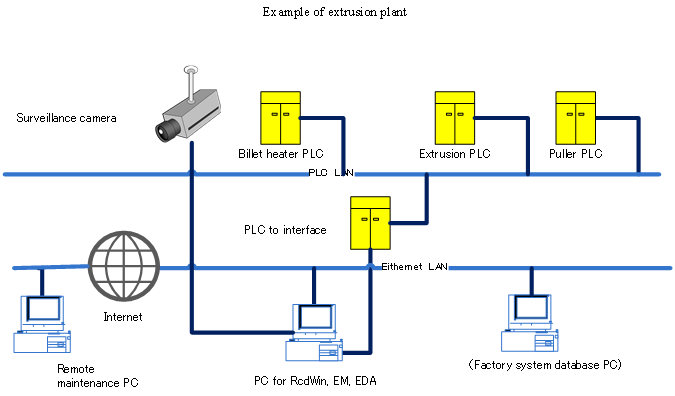

システム構成

IPネットワーク対応の監視カメラが必要です。監視カメラ性能は以下です。

1 レンズタイプ:光学20~30倍ズームオートフォーカスレンズ。

2 200万画素数。

3 遠隔コントロール可能(スマホ/PC)。

4 PTZモード:プリセット/スキャン/パトロール/ツアー。

プログラムのテストには、SUNBA 406-D20X-PoEを使用しました。ズームして画像を取るので、早い製品速度の場合はカメラのシャッタースピード(フレームレイト)に注意が必要です。 405-D20X-PoEは、シャッタースピードが仕様に表示されています。シャッターコントロール:1/1 ~ 1/30000s。こちらの製品の方が安心です。

図1-1 監視カメラをRcdWin,EM,EDAプログラムのシステムに追加しました。監視カメラは通信量が多いので、監視カメラ専用にUSB LANアダプタを追加しました。

↑TOP of Page

2

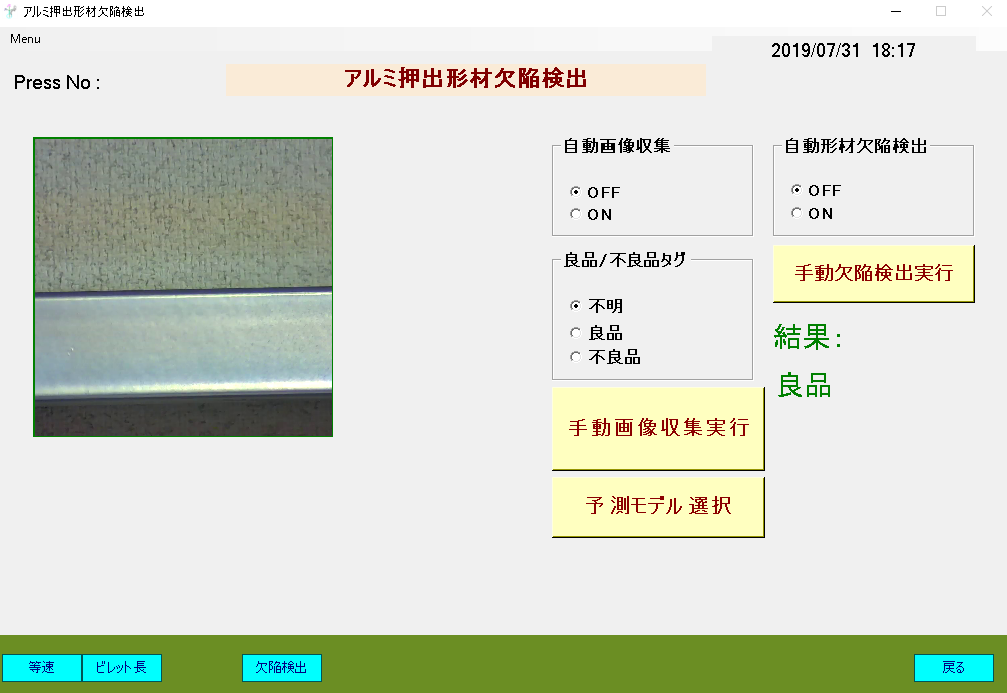

アルミ押出形材欠陥検出画面

通常は、プログラムは自動で良品の画像を収集することになると思います。

不良品ができた場合は、手動にして画像を収集することになると思います。

ディープラーニングの場合は、押出中ではなく、押出後の不良品の画像をカメラで保存しても、予測モデル作成のデータとして問題ないはずです。

押出作業者は、押出中も押出後も不良は不良として認識できるからです。

画面には、以下の機能があります。

- 押出形材の表示(写真は、実際の工場の押出現場ではありません)。

- 自動/手動の欠陥検出の設定。

- 自動/手動の画像収集の設定。

- 予測モデルの選択。

図番2-1 アルミ押出形材欠陥検出画面 (押出中の映像ではありません)

↑TOP of Page

3

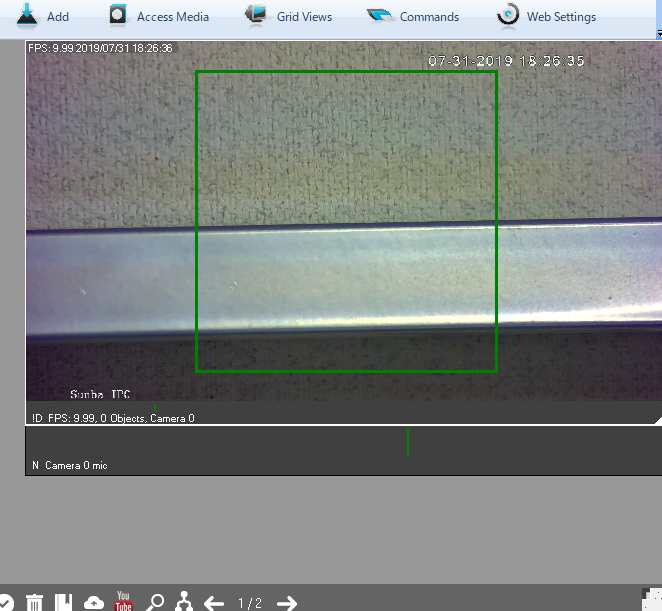

iSpyのプラグインで画像取得

iSpyは無料の監視カメラ用ソフトです。

iSpyのプラグインを作ることにより、ソフトの機能を拡張できます。

自作したプラグインで、400×400ピクセルの正方形の部分だけを、押出管理プログラムに転送しています。

プラグインで画像の光の反射を軽減したり、ディープラーニングのデータとして問題がないように画像の加工処理が行えます。

図番3-1 iSpyで監視カメラの映像を表示します。プラグインを使用して、正方形の画像を押出管理プログラムに送信します。 (押出中の映像ではありません)

↑TOP of Page

4

監視カメラの調整

監視カメラの映像のズームや方向の変更は、IEで監視カメラのIPアドレスにアクセスすれば行えます。

カメラのコントロールは、iSpyよりカメラのWebの方が使いやすいです。

図番4-1 IEで監視カメラのIPアドレスにアクセスする。カメラの調整が行えます。 (押出中の映像ではありません)

↑TOP of Page