押出管理

EM

RCDIGITAL,Inc.

May 2019

1

押出管理

押出管理プログラムの特徴

-

押出ダイス単位で,等速押出、等温押出のパラメータの登録、変更、検索が可能です。

-

等速押出、等温押出のパラメータを機械にセットできます。

-

押出ダイス単位の押出スケジュールを作成できます。

-

システムのデータベースから押出スケジュールを取得することもできます。

-

放射温度計の放射率の自動調整ができます。

- 押出速度が製品速度の[m/min]でも、そのまま運用が可能(押出比でラム速度に変換します)。

-

ビレット長スケジュールのシミュレーションが5つのモードでできます。

押出管理では、画面ごとに機械のパラメータを計算して、ネットワークに接続した機械にパラメータをセットできます。

随時、新しい機能を開発中です。

注>

機械のパラメータがアナログ設定の場合は、タッチパネルなどデジタル設定に変更する必要があります。

↑TOP of Page

2

押出管理プログラムの事例

2-1

製品速度をラム速度に変換

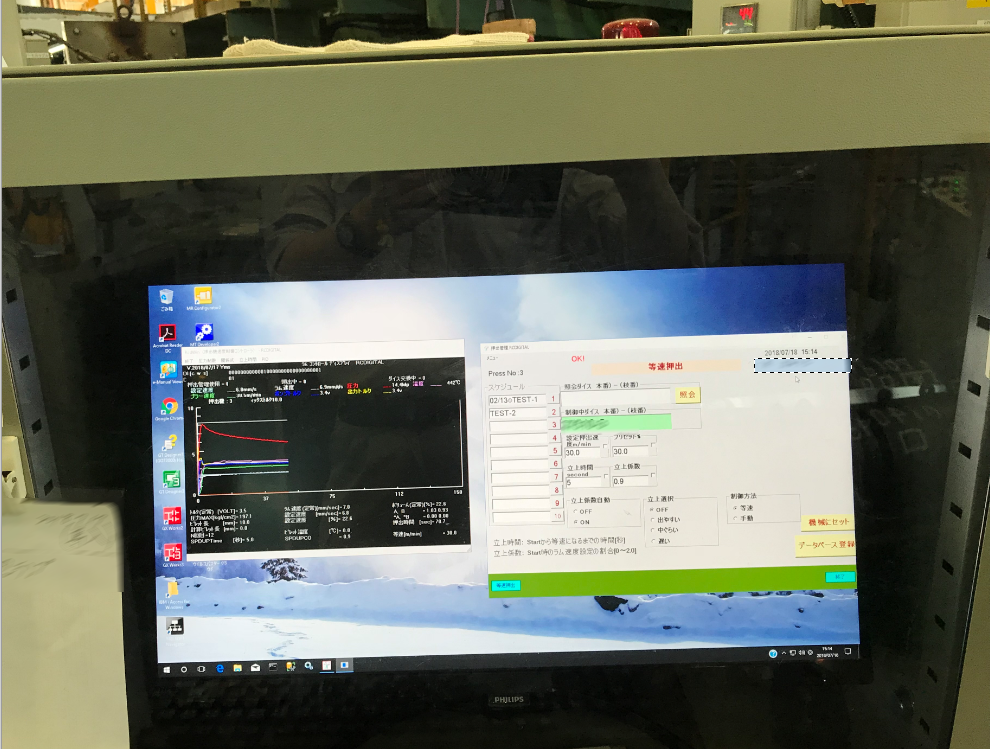

- パソコン盤内のプログラムの画面。

-

押出管理で設定押出速度[m/min]を、押出比でラム速度に変換して等速押出を行います。ラム速度ではなく、製品速度で押出速度を管理している会社の場合に使用します。

図番2-1 製品速度をラム速度に変換

↑TOP of Page

2-2

ラム速度の設定の自動化

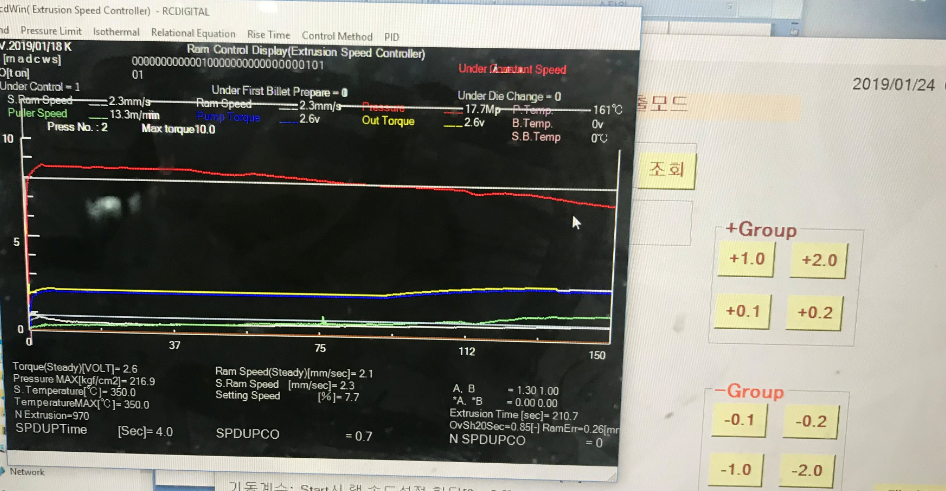

- キーボードでラム速度の入力が必要ありません。ラム速入力にマウスを使用します。

-

[機械にセット]ボタンの実行が必要ありません。マウス入力がそのまま、機械に入力されます。

図番2-2 ラム速度設定の自動化

↑TOP of Page

2-3

工場システムから押出ダイススケジュールを取得

-

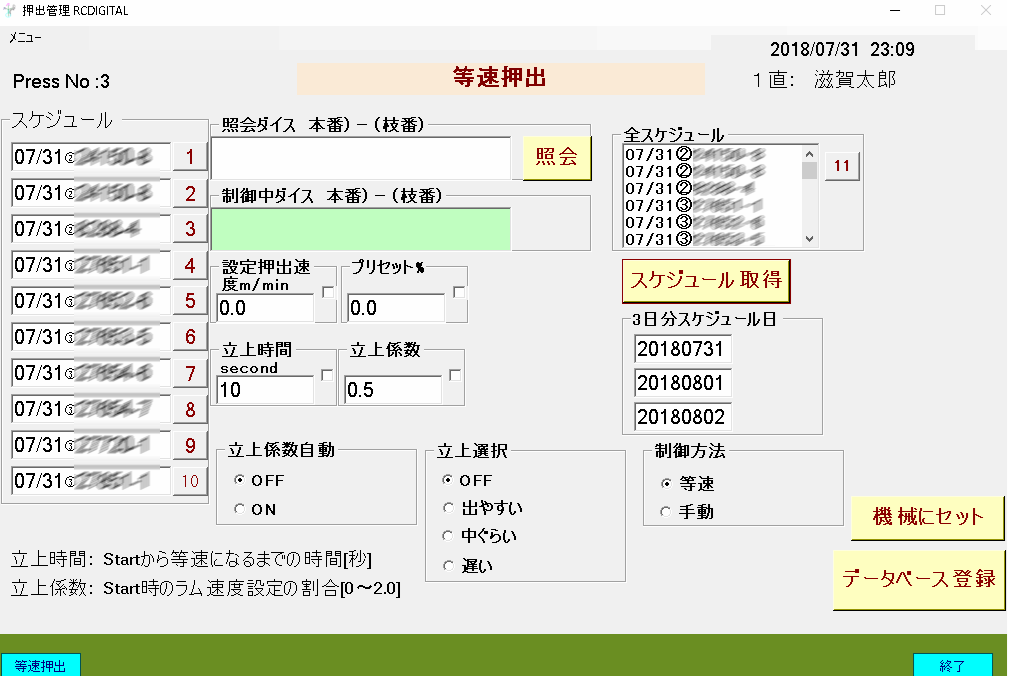

[スケジュールの取得]ボタンを実行すると、[全スケジュール]には、3日分のスケジュールが表示されます。[スケジュール]には、1日目の10日分が表示されます。

処理済の押出ダイスは表示されません。

押出管理(EM)での押出ダイスの処理終了は、[機械にセット]ボタンを実行で処理済とします。

-

[機械にセット]ボタンを実行で、画面の押出パラメータが機械にセットされます。

-

[データベース登録]ボタンを実行すると、データベースに押出パラメータが登録されます。

-

[制御方法]で[手動]を選択すると、作業者のボリューム値(プリセット値)を、トルク(流量)として出力します。

図番2-3 工場システムから押出ダイススケジュールを取得

↑TOP of Page

2-4

等温押出の押出管理

-

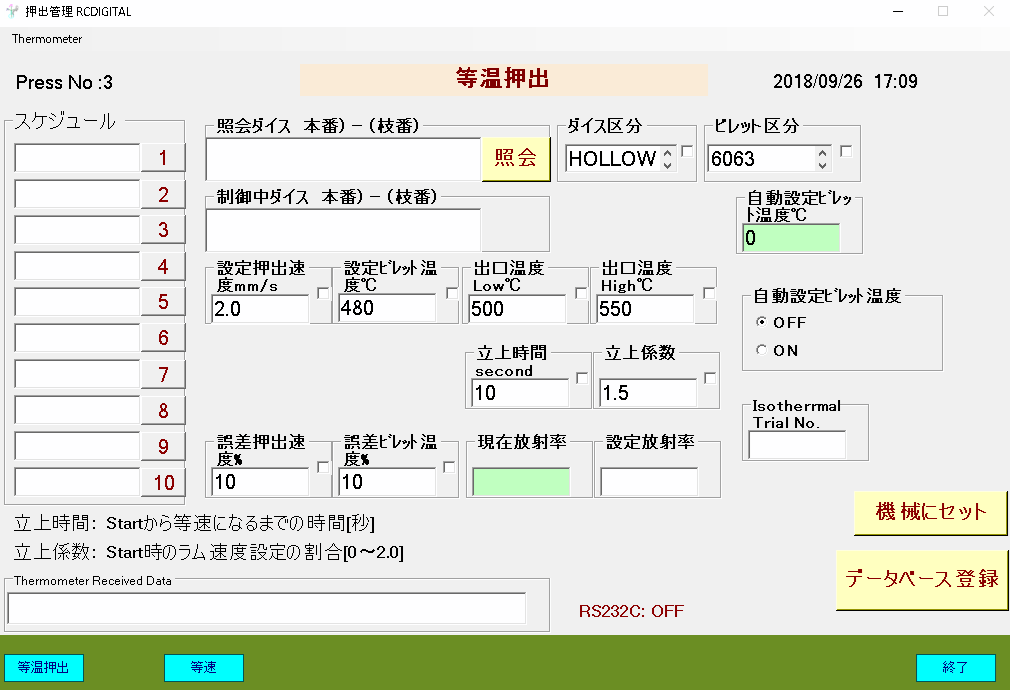

[機械にセット]ボタンを実行で、画面の押出パラメータが機械にセットされます。

-

[データベース登録]ボタンを実行で、データベースに押出パラメータが登録されます。

温度の設定は、[出口温度Low]と[出口温度High]で行います。

-

[自動設定ビレット温度]をONにすると、自動でビレット温度を調整します。初期値は[設定ビレット温度]です。計算したビレット温度は、緑の[自動設定ビレット温度]に表示されます。

自動設定ビレット温度は、立上り係数の自動だけでは、温度の立ち上がりが遅い場合に使用します。

-

[誤差押出速度]は、[設定押出速度]の許容誤差です。

-

[誤差ビレット温度]は、[設定ビレット温度]の許容誤差です。

図番2-4 等温押出の押出管理

↑TOP of Page

2-5

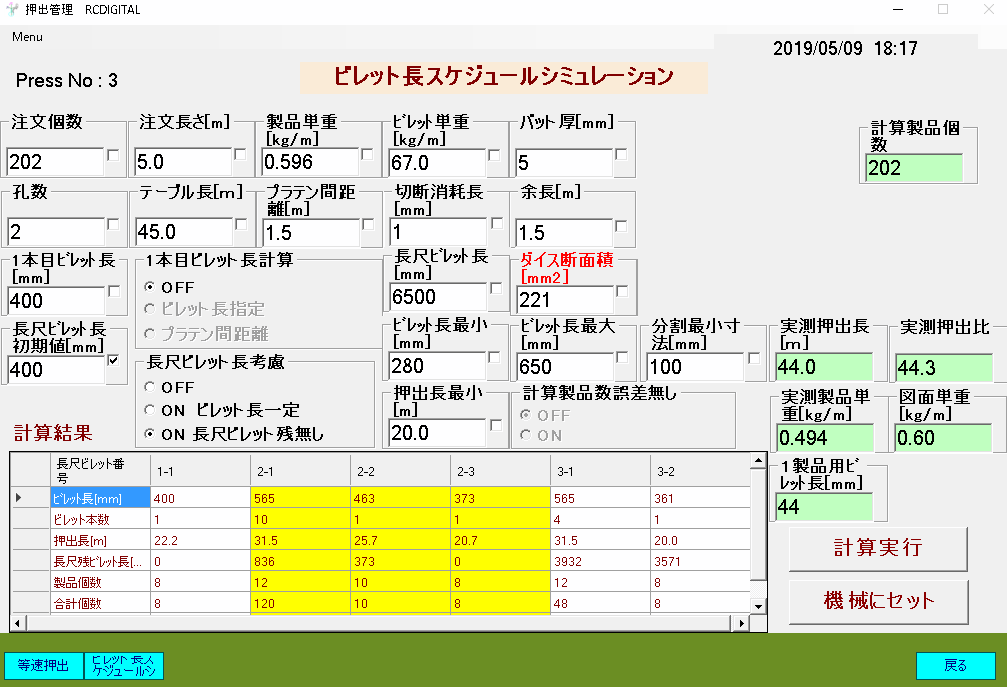

ビレット長スケジュールシミュレーション

シミュレーションの説明

長尺ビレット長を考慮して、押出のビレット長が一定になるように、ビレット長のスケジュールをシミュレーションします。

- 最大ビレット長は565[mm]ですが、1本目ビレット長が400[mm]なので、1-1は、400[mm]となります。

- 2本目の長尺ビレットは、565[mm]が10本、463[mm]が1本、373[mm]が1本です。全部で6500[mm]です。

長尺ビレットを使い切ってきます。

- 3本目の長尺ビレットは、565[mm]が4本、361[mm]が1本、373[mm]が1本です。注文個数分のビレット長をスケジュールしたので終了です。

図番2-5 ビレット長を計算する時に、長尺ビレット長の残りを0にして、長尺ビレットを使い切ります。

↑TOP of Page