ビレット長スケジュールシミュレーション

EM

押出管理

RCDIGITAL,Inc.

May 2019

1

ビレット長スケジュールシミュレーション

押出作業現場で便利に使用できるビレット長スケジュールシミュレーションプログラムです。

工場のシステム部門は、押出ダイス毎に、ビレット長とビレットの本数を計算します。ビレット長は最大になるようにします。

しかし、押出作業者は製品の歩留りを良くするために、そのビレット長を変更しながら押出作業を行います。

理由は、長尺ビレットの残を押出に使用する、押出長さの変化(製品単位重量が熱により変化します)、不良の発生などがあるからです。

長尺ビレットは高価なものなので、無駄にしないことが求められます。

1-1ビレット長スケジュールのための5つのモード

- 長尺ビレット長を考慮して、ビレット長を一定にします。例えば、ビレット長が600[mm]の時に、長尺ビレットの残りが400[mm]だとします。

次の長尺ビレットの最初の切断は200[mm]になります。

- 長尺ビレットの残りがないようにビレット切断計画をシミュレーションします。例えば、長尺ビレットの残りが100[mm]の時は、その前に計画した幾つかのビレット長を短くします。短くした分を、

100[mm]のビレット長に振分けます。その結果、最後のビレットも押出ができるようになります。

- 長尺ビレットを考慮しないモード。1本目のビレット長を指定します。その他は、ビレット長が最大になるように、注文個数分のビレット長スケジュールをシミュレーションします。

- 長尺ビレットを考慮しないモード。1本目のビレット長をプラテン間距離で計算します。その他は、ビレット長が最大になるように、注文個数分のビレット長スケジュールをシミュレーションします。

- 長尺ビレットを考慮しないモード。1本目のビレット長を指定しないで、注文個数分のビレット長スケジュールををシミュレーションします。

1-2

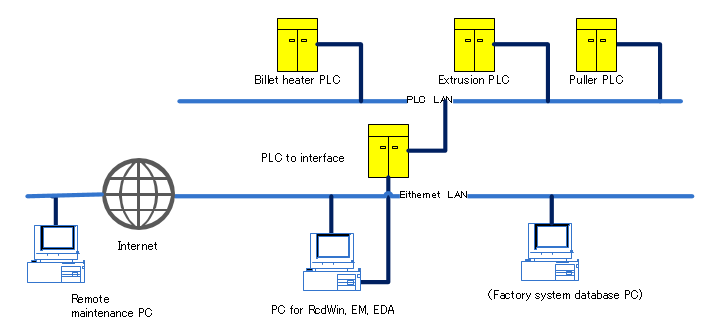

押出管理パソコン、工場のシステムデータベース、プラーPLC,ビレット切断PLCのネットワーク構成の利点

- 注文個数、ダイス断面積などをシステムデータベースから取得できます。

- ビレット切断PLCにビレット長切断計画を送信できます。

- 計測した押出長さから、製品単位重量を計算して、正確なビレット長が計算できます。

図1-1 RcdWin,EM,EDAプログラムのパソコンが、工場のシステムデータベース、プレスPLC,プラーPLC,ビレット長切断PLCとネットワークで接続しています。

↑TOP of Page

2

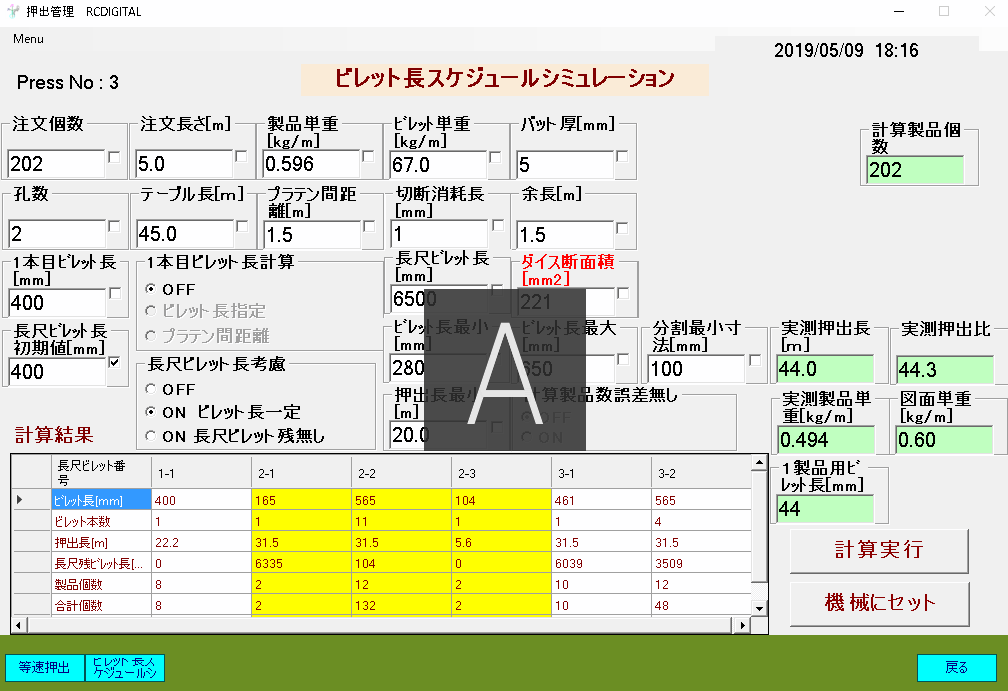

長尺ビレット考慮(ビレット長一定)

シミュレーションの説明

長尺ビレット長を考慮して、押出のビレット長が一定になるように、ビレット長のスケジュールをシミュレーションします。

注文個数分のビレット長スケジュールを計算します。

- 最大ビレット長は565[mm]ですが、1本目ビレット長が400[mm]なので、1-1は、400[mm]となります。

- 2本目の長尺ビレットの2-1は、165[mm]です。1-1の400[mm]を足すと、565[mm]になります。2-2は、565[mm]が11本です。2-3は104[mm]ビレットが1本です。

- 3本目の長尺ビレットの3-1は、461[mm]が1本になります。2-3の104[mm]を足すと、565[mm]になります。3-2は、565[mm]が4本です。注文個数分のビレット長をスケジュールしたので終了です。

図番2-1 長尺ビレットを考慮してビレット長を一定にするビレット長スケジュール

↑TOP of Page

3

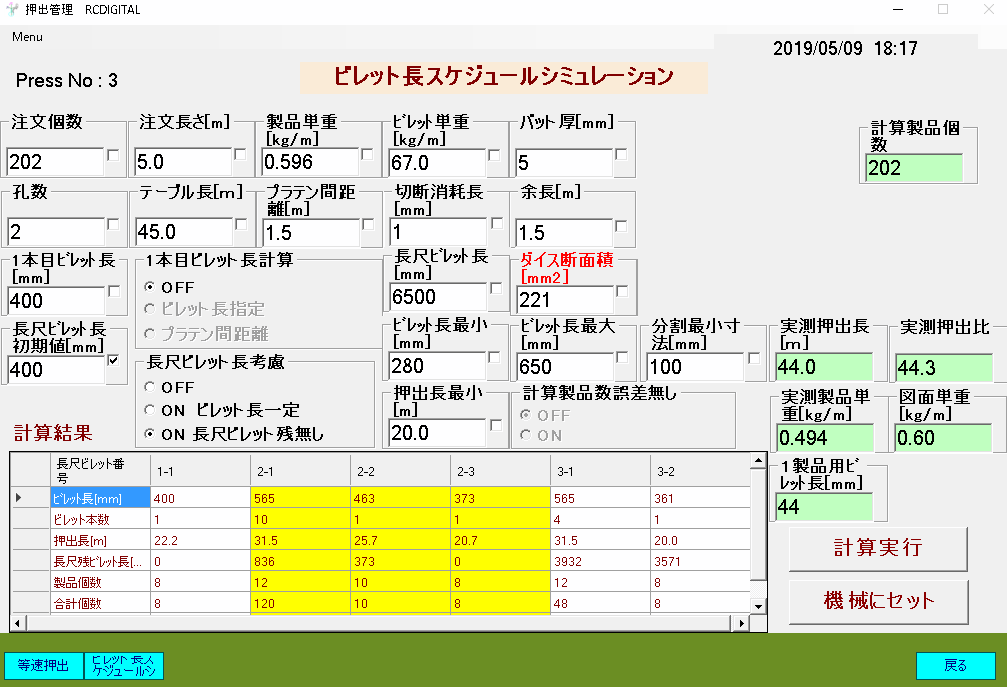

長尺ビレット考慮(使い切り)

シミュレーションの説明

長尺ビレット長の残りがないように、ビレット長スケジュールを計算します。

注文個数分のビレット長スケジュールを計算します。

- 最大ビレット長は565[mm]ですが、1本目ビレット長が400[mm]なので、1-1は、400[mm]となります。

- 2本目の長尺ビレットは、565[mm]が10本、463[mm]が1本、373[mm]が1本です。全部で6500[mm]です。

長尺ビレットを使い切ってきます。

- 3本目の長尺ビレットは、565[mm]が4本、361[mm]が1本、373[mm]が1本です。注文個数分のビレット長をスケジュールしたので終了です。

図番3-1 ビレット長を計算する時に、長尺ビレット長の残りを0にして、長尺ビレットを使い切ります。

↑TOP of Page

4

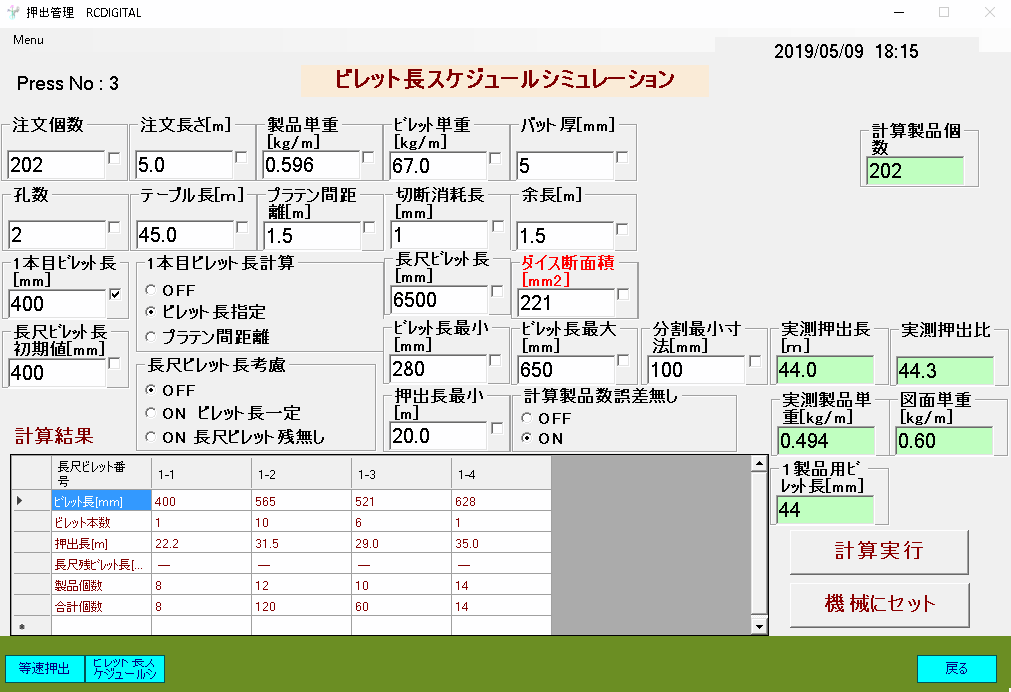

1本目のビレット長指定

シミュレーションの説明

1本目のビレットはビレット長を指定します。2本目以降は、最大ビレット長を計算します。

注文個数分のビレット長スケジュールを計算します。

- 1-1は、指定したビレット長の400[m]が1本になります。

- 1-2は、最大ビレット長565[mm]が10本になります。

- 1-3は、521[mm]が6本です。

- 1-4は、注文個数と計算製品個数を等しくするために、628[mm]を1本にします。

図番4-1 1本目では、ビレット長を指定して、注文個数分のビレット長スケジュールを計算します。

↑TOP of Page

5

プラテン間距離指定(1本目ビレット長用)

シミュレーションの説明

1本目のビレットは、プラテン間距離を考慮します。2本目以降は、最大ビレット長を計算します。

注文個数分のビレット長スケジュールを計算します。

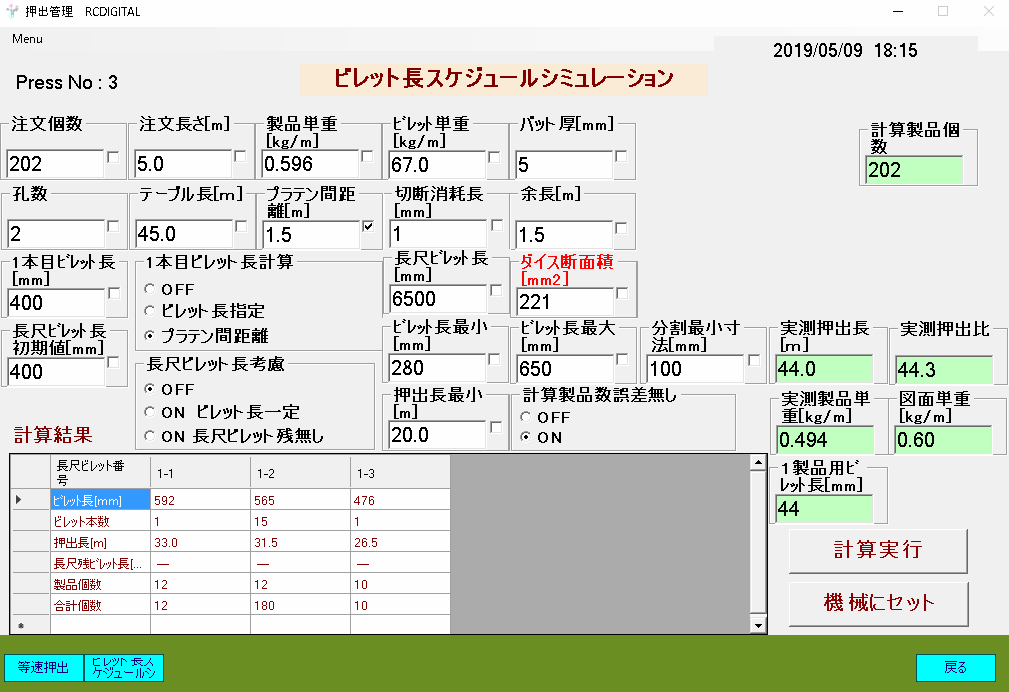

- 1-1は、プラテン間距離を考慮して592[mm]が1本になります。

- 1-2は、最大ビレット長565[mm]が15本になります。

- 1-3は、521[mm]が6本です。

- 1-3は、注文個数と計算製品個数を等しくするために、476[mm]を1本にします。

図番5-1 1本目はプラテン間距離を考慮します。注文個数分のビレット長スケジュールを計算します。

↑TOP of Page

6

普通のビレット長スケジュール計算

シミュレーションの説明

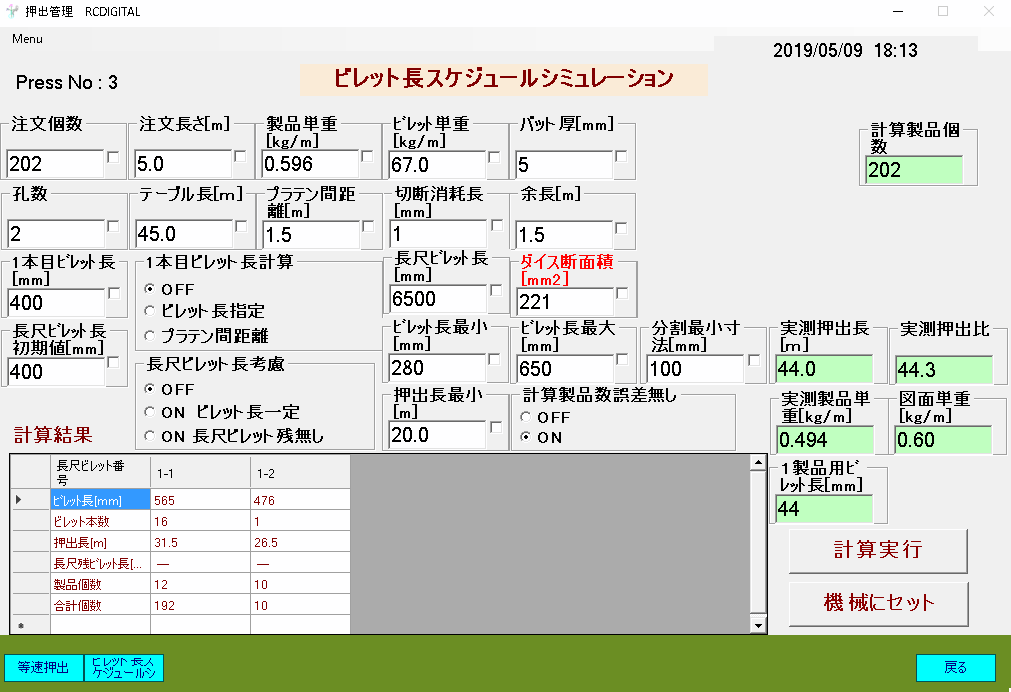

最大ビレット長を計算します。注文個数分のビレット長スケジュールを計算します。

- 1-1は、最大ビレット長の565[mm]が16本になります。

- 1-2は、注文個数と計算製品個数を等しくするために、476[mm]を1本にします。

図番6-1 注文個数分のビレット長スケジュールを計算します。

↑TOP of Page