押出データ解析

EDA

RCDIGITAL,Inc.

May 2019

1

押出データ解析

1-1特長

アルミ押出工場をIT化します。

等速押出と等温押出(RcdWin)、押出管理(EM)、押出データ解析(EDA)がデータベースに保存したデータを利用して、以下のような機能があります。

-

押出データの帳票とグラフ化。

-

設備の異常データの検出。

-

アルミ押出機の停止時間(アイドルタイム)と少しの停止(チョコ停)と押出ダイス交換時間のCSVファイル化。

-

押出パラメータの押出ダイスごとの履歴(押出速度など)。

-

押出ダイス使用履歴。

-

リアルタイムモニタ。

-

歩留り。

1-2

メンテナンスと拡張性

RcdWinパソコンはLAN上で稼働するので、工場の生産管理システムと連携して、押出の自動化ができます。

押出パラメータを自動的に収集して、押出パラメータを自動で調整します。

押出データ解析プログラム(EDA)にデータを送信して、EDAで押出データの解析が行えます。

メンテナンスは、インターネットを通してリモートで行います。

RcdWin,EDA,EM,EP,RcdWinMoniと押出データベースは、1つのパソコンで動作します。

↑TOP of Page

2

押出ダイス選択画面

[押出ダイス番号]を選択して、[押出ダイス使用履歴]クリックします。

-

[押出ダイス使用履歴]画面に遷移します。

図番2-1 押出ダイス選択画面

-

[非押出時間Xlsxファイル]をクリックします。

-

押出のEndから押出のStartまでのアイドル時間が、グラフでXlsxファイルに出力されます。

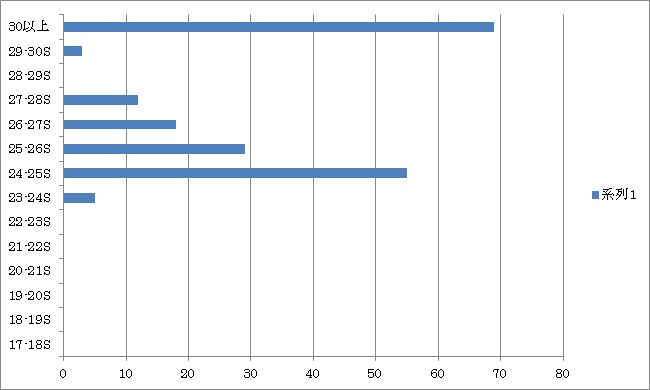

図番2-2 非押出時間(押出機アイドルタイム)Xlsxファイル

↑TOP of Page

3

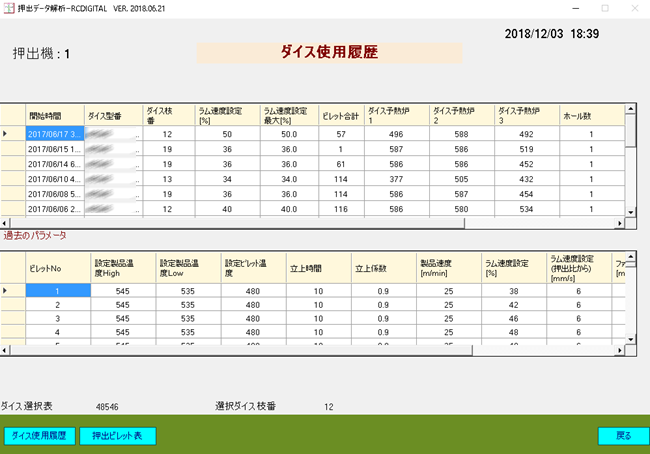

押出ダイス使用履歴

-

押出ダイスの使用履歴を新しいものから順番に表示します。

-

選択した日の押出ダイスの押出パラメータを下段の表に表示します。

-

[押出ビレット表]を実行すると、選択した日の押出ダイスの帳票印刷画面に遷移します

0

図番3-1 押出ダイス使用履歴

↑TOP of Page

4

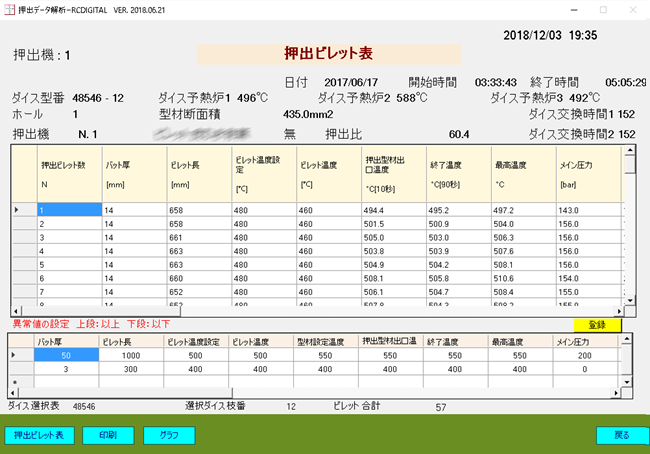

押出ビレット表

-

[印刷]ボタンの実行で、プリンタ、Excel,PDF,Wordに帳票を印刷できます。

-

[グラフ]ボタンの実行で、押出過程をグラフで見ることができます。

-

下段の表で計測データの異常値の設定ができます。上段は異常値以上で、下段は異常値以下です。異常値には、帳票の数値の値の前に**が付きます。

図番4-1 押出ビレットテーブル

4-1

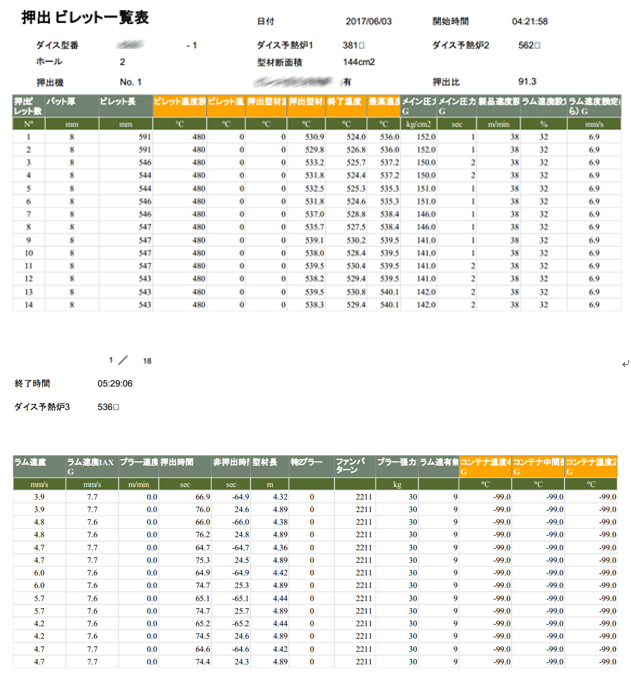

押出ビレット一覧表の例

-

帳票の表示する項目は、工場によって異なりますが、印刷する帳票は、A4横で3ページぐらいになります。

-

エクセルの場合は、ファイルで開くと、行の全体が1行で見ることができます。

図番4-2 押出ビレット一覧表

↑TOP of Page

5

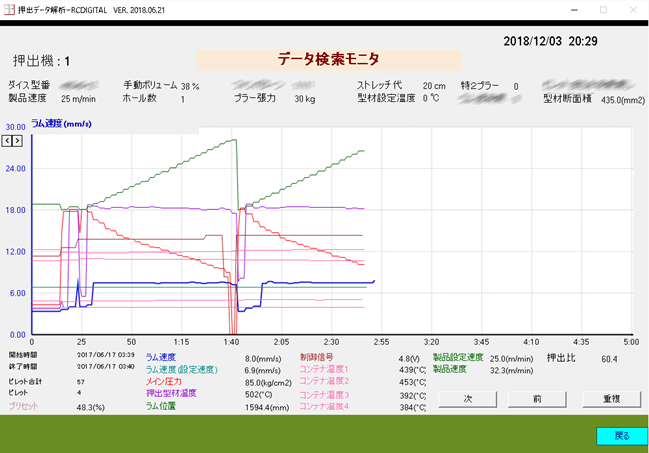

押出データ検索

lblEdaS5003

図番5-1 押出データ検索

↑TOP of Page

6

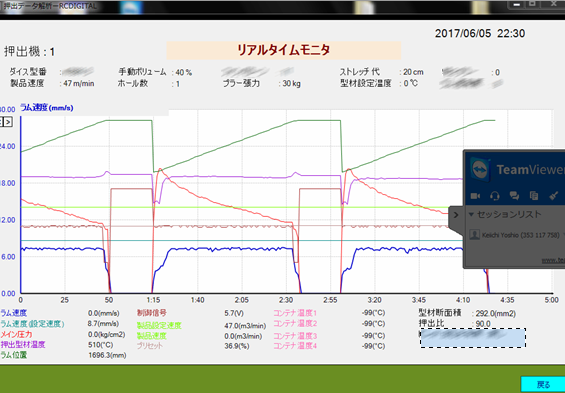

リアルタイムモニタ

-

押出状況をリアルタイムのグラフで見ることができます。

図番6`-1 リアルタイムモニタ

↑TOP of Page

7

製品の歩留り

-

押出ダイスのロット単位の良品個数を参照して、指定した期間の歩留まりを計算します。

-

同じ押出ダイスが2回でてきた場合は、2回目のダイスの良品個数は累計になります。

-

終了メッセージがNoの場合は、まだ良品個数が入力されていません。

図番7-1 Product yield

↑TOP of Page