Extrusion Data Collection Database RCC

|

1 |

|||

|

2 |

|||

|

3 |

|||

|

4 |

|||

|

|

|||

1 The extrusion process can be easily accomplished by collecting the following extrusion data (Pin point and real time log data) and registering them with the database. The registered data can be used for various kinds of research analysis such as product defective cause survey and uniform temperature control.

(Note: Although most of the data are automatically collected, it can also be set from the touch panel and database,)

*New Note: Uniform temperature

extrusion is possible by

rcdWin which runs in the .NET platform of

Windows XP.

*New Note: rcdWinMoni can monitor the data

of 20,000 extrusions which is colleted by rcdWin and can edit the data by Excel.

● Pinpoint Data

Year/Month/Day/Time/Minutes/Seconds/Die No. (the parents No.)/Die No. (the branch No.)/Billet Makers/Die Temperature Setting Value/Billet Temperature Setting Value/Container Temperature Setting Value/Billet Length/ Extrusion Length/Die Types (hollow or solid)/Sash Temperature Max/Sash Temperature in First Half/Sash Temperature in Intermediate/Sash Temperature in Second Half/Setting Ram Speed/Puller Speed Max/Ram Speed Max/Pressure Max/Pressure Max Time/Aluminum-skin Condition/Anodized Aluminum Color/etc.

Storage is possible up to twenty thousand extrusion with the default parameters.

● Real Time Log Data

The control process graph can also be displayed by using the real time log data. In this way, four thousand different extrusions can be stored with the default parameters.

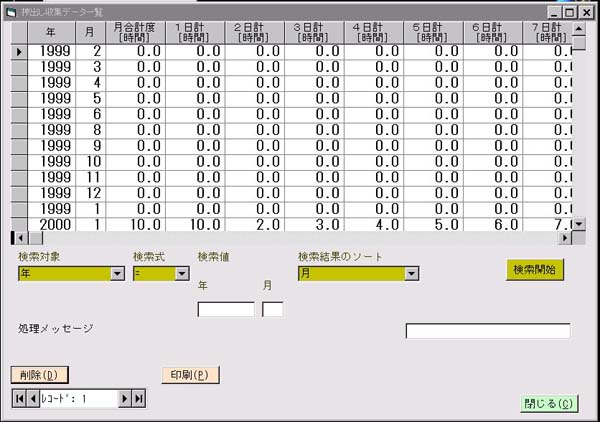

2 The total operation time per month or day of the extrusion press can be shown.

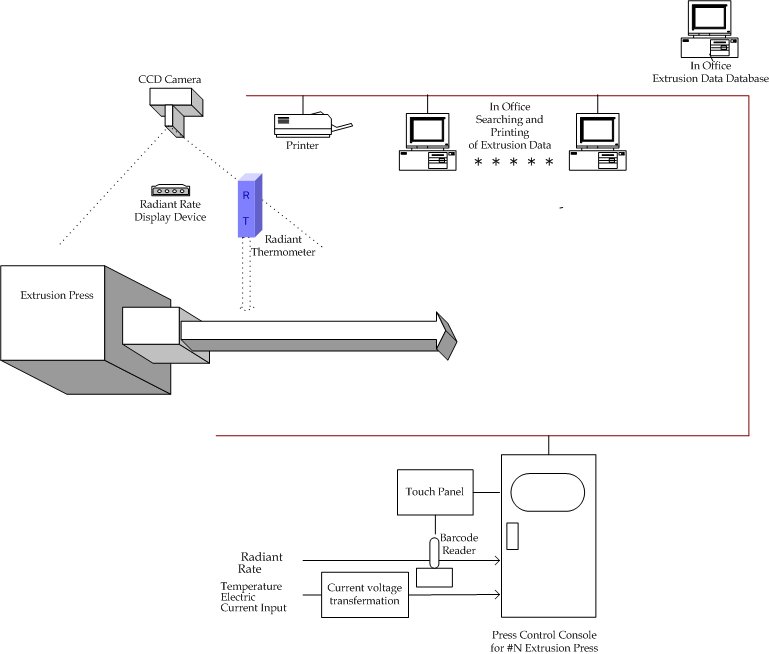

3 System Constitution Diagram

1 The temperature graph of the radiation thermometer and the video screen of the CCD camera are displayed on the touch panel during ram speed control.

2 The total of the operation time of the day and month and stoppage time of the extrusion press are displayed on the touch panel. The start stoppage on a day is displayed in the graph.

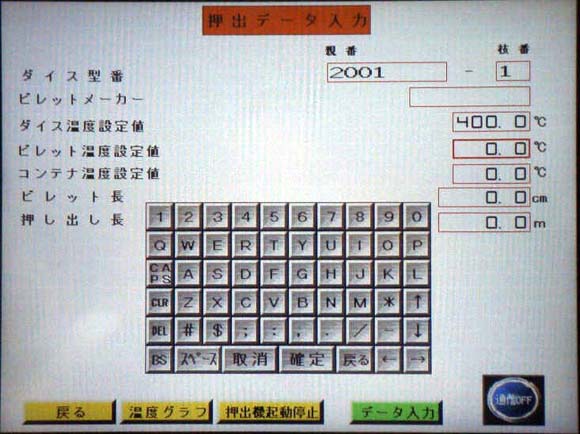

3 A specific extrusion from the database can be searched by using specific parameters (Die No. ( parents No.), Die No. (branch No.), Billet Makers, Die Temperature Setting Value) if the parameters have been inputted by the touch panel during each die replacement.

|

Menu Screen of Extrusion data Collection Database |

|

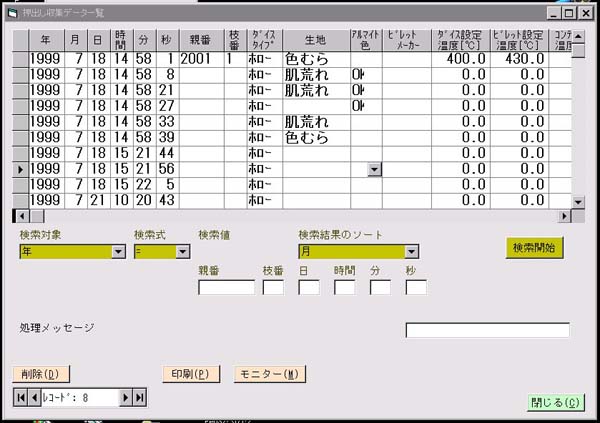

When [Extrusion Data DB] button in the menu is clicked, this is displayed. The extrusion data of each billet can be searched with this screen. |

|

When [Monitor] button is clicked after searching for the specific billet, the control process is monitored with the graph. |

|

When [Extrusion Start Stoppage Time] button in the menu is clicked, this is displayed. The total operation time of the day and month and stoppage time of the extrusion press can be searched on this screen. |

|

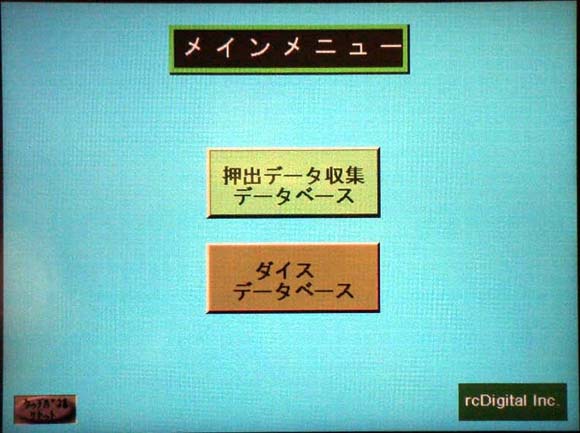

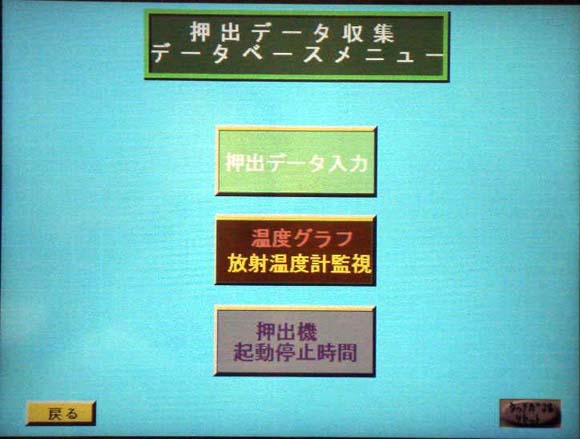

| Extrusion Data Collection Database and Dies Database Menu Screen on the touch panel |

|

Extrusion Data Collection Database Menu Screen on the touch panel |

|

When [Extrusion Data Input Screen] button is clicked, this is displayed .The value that is inputted here is possible to input at the the personal computer in the office using the database. The searching of billets is possible by the time of when when it was extruded.. |

|

When [Temperature Graph and Radiation Thermometer Surveillance] button is clicked, this is displayed. It shows the CCD camera's video screen and the temperature graph of aluminum sash in extrusions. |

|

When [Extrusion start stoppage time] button in is clicked, this is displayed. Extrusion operation time graph in the day, the start stoppage time of the day and month are displayed. |

Copyright © 1997,2004 All rights reserved rcDigital Inc.