Dies Database DIES

|

1 |

|||

|

2 |

|||

|

3 |

|||

|

4 |

H O M E

By registering the control information in the dies database and linking it with the controller there are the following advantages.

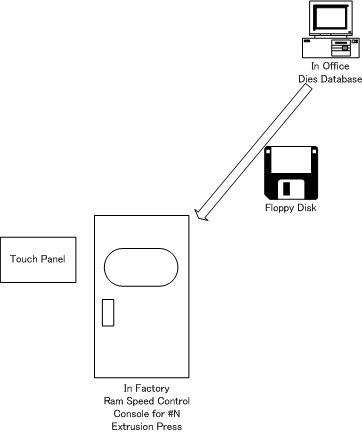

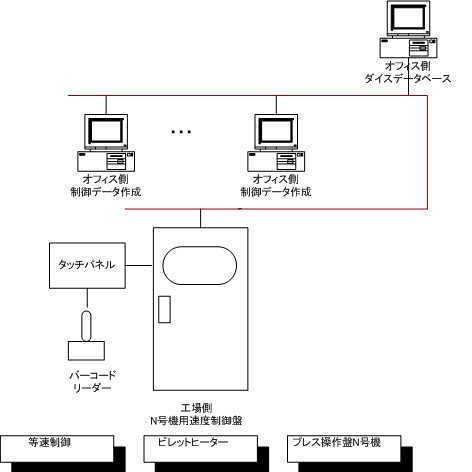

At present, the link with the dies database is possible through the method shown in Figure 6-1. The operator inputs the die numbers from the touch panel. The controller does the first billet head control and uniform velocity control in accordance with the control information in the database. A LAN connection like that shown in Figure 6-2 is also possible.

Figure 6-1System Constitution Diagram

Figure 6-2 System Constitution Diagram

Usually, the operator extrudes the first billet head of a die by varying the control volume up and down, but the controller does it automatically. The processing flow is as follows.

The fourth step above happens when the product is caught by the puller. Yet, if there is no puller, the second cycle stop does not come readily, and the controller regards that signal as off.

The control method is divided into two types of dies, a hollow die and a solid die.

Without connecting with the dies database the first billet head control is possible only with the usage of the first billet head signal.

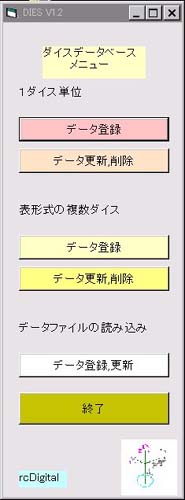

Dice Database Screen

|

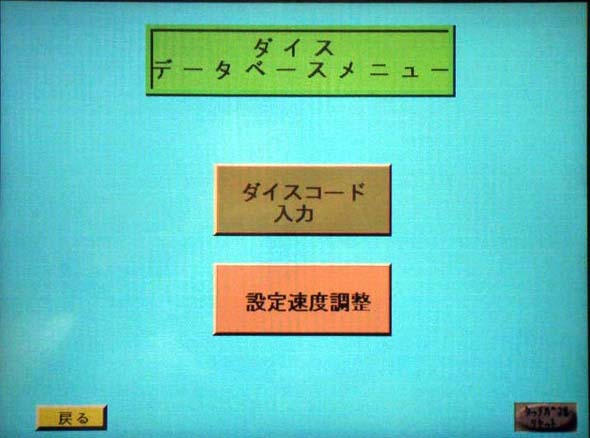

Menu Screen of Dies Database |

|

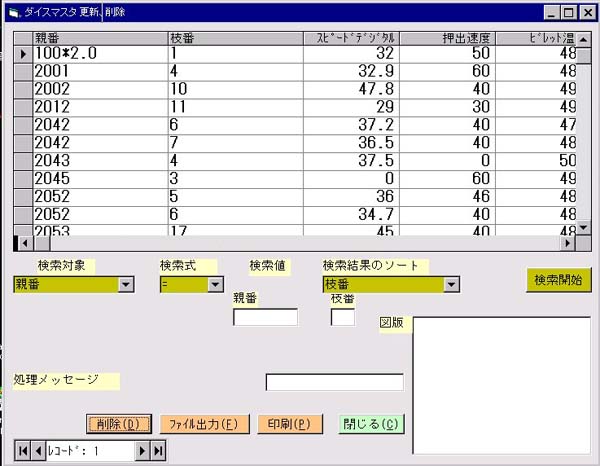

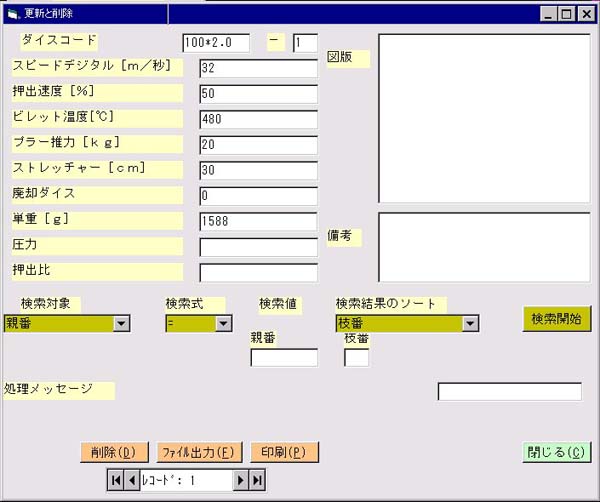

This screen is displayed when [Data Renewal, Elimination by Table Format] button is clicked from the main menu. Here, the ram speed control information for each die can be set. |

|

This screen is displayed when [Data Renewal, Elimination for a Die] button is clicked from the main menu. Here, the ram speed control information for each die can be set. |

Touch Panel Screen

|

| Dies Database Menu Screen of the Touch Panel |

|

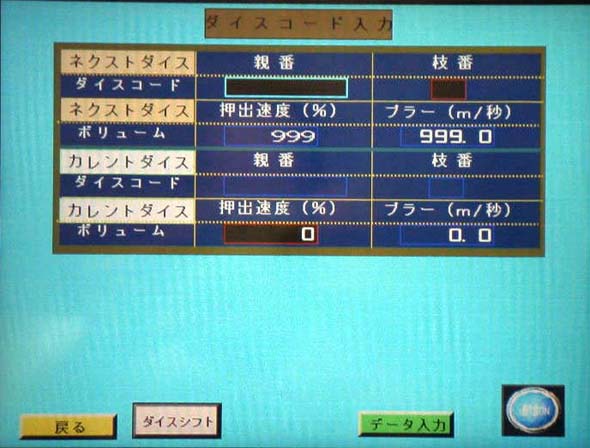

Dies Codes Input Screen-ram reference speed and puller reference speed are searched from the Dies Database in the computer when a die code is set. |

Copyright © 1997,2004 All rights reserved rcDigital Inc.